|

<< Click to Display Table of Contents >> Results Tab |

|

|

<< Click to Display Table of Contents >> Results Tab |

|

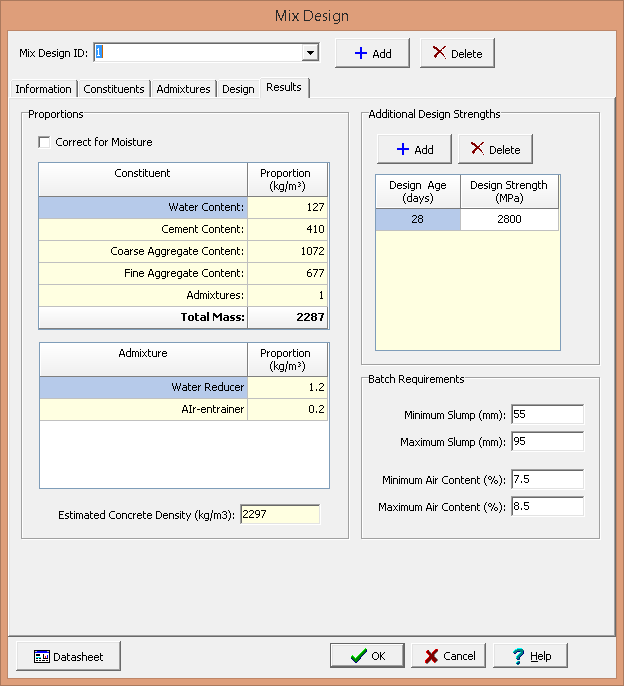

The results of a mix design consist of a set of proportions that will produce the required concrete properties. This tab is used to display the results of the mix design and to specify any additional strength and batch requirements.

The following is displayed or specified on this tab:

Proportions

Correct for Moisture: Check this box to correct the proportions for moisture. This will correct for moisture absorbed in and on the surface of aggregates. The proportions of the coarse and fine aggregates will be increased by the moisture contents specified on the Constituents tab. And the water content will be decreased by differences between the moisture content and absorption of the coarse and fine aggregates.

Constituent Proportions: The proportions calculated for each constituent is displayed.

Admixture Proportions: The proportions calculated for each admixture is displayed.

Estimated Concrete Density: This is the estimated concrete density. It is the total of all the proportions per unit volume. When calculating the density, the coarse and fine aggregate masses are corrected for water absorption.

Additional Design Strengths

Additional design ages and strengths can be added and removed using the Add and Delete buttons. For each design age selected the design strength can be specified.

Batch Requirements

Minimum Slump: This is the minimum slump for batch requirements. Typically it is 20 mm (0.75 in) less than the design slump.

Maximum Slump: This is the maximum slump for batch requirements. Typically it is 20 mm (0.75 in) greater than the design slump.

Minimum Air Content: This is the minimum air content for batch requirements. Typically it is 0.5 % less than the design air content.

Maximum Air Content: This is the maximum air content for batch requirements. Typically it is 0.5 % greater than the design air content.